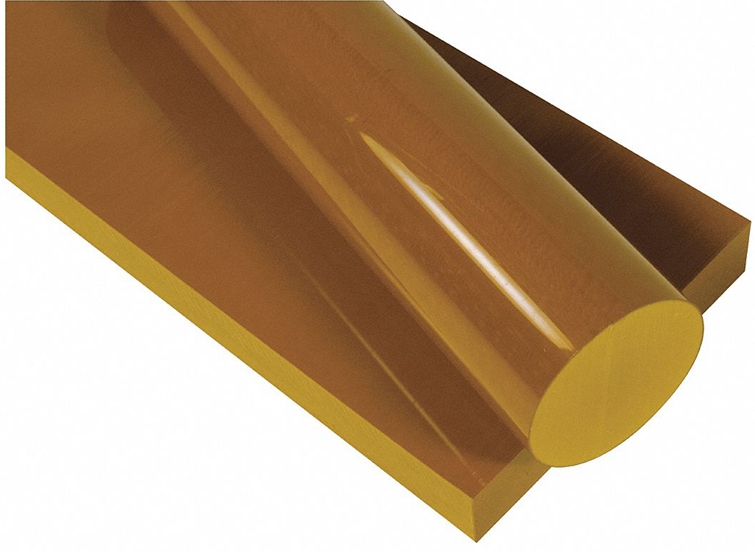

Torlon®Quadrant Pai Torlon 4203 Sheet polyamide-imide offers excellent compressive strength and the highest elongation of the Torlon® grades. It also provides electrical insulation and exceptional impact strength. This Torlon grade is commonly used for IC Test Sockets & Handlers, as well as, electrical connectors and insulators due to its high dielectric strength. Its ability to carry high loads over a broad temperature range makes it good for structural components such as linkages and seal rings. Torlon®4203 is also an excellent choice for wear applications involving impact loading and abrasive wear.

- Torlon 4203 is BROWN in color.

The parts processed by Duratron®T4203 PAI have a high level of tensile strength and compression resistance to ensure that the parts have good mechanical load capacity. In addition, Torlon material has higher toughness and rigidity. Mechanical rigidity, low thermal expansion coefficient and thermal stability help to obtain dimensionally stable finished parts. It is possible to modify PAI plastics, usually adding glass fiber or carbon fiber to improve strength and stiffness, or adding PTFE or other lubricants to reduce friction and improve wear resistance, including dry running conditions. However, the high hygroscopicity of Torlon material may cause dimensional changes and is sensitive to exposure to saturated steam. Torlon PAI material has an excellent balance of mechanical properties, electrical properties, chemical resistance, thermal properties and friction properties, and has good performance in extreme high temperature conditions.

Features of Torlon Pai Sheet Rod & Tubes:

- Very High Compressive Strength (24,000 psi)

- Very High Impact Strength - IZOD Notched Impact of 2.0 (ft-lb/in)

- Maximum 500° F Continuous Operating Temperature

- Tremendous Insulation Properties & High Dielectric Strength (580 V/Mil - short-term)

- Note: Torlon 4203 is prone to moisture absorption (0.4% at 24 hours)

- Full-Length Torlon 4203 Rods are 96" long (2440mm) - rods will be cut in-half for shipping unless otherwise stated

- Rods may be cut for convenient shipping unless otherwise specified.

- Available from Professional Plastics USA, Singapore & Taiwan Warehouses

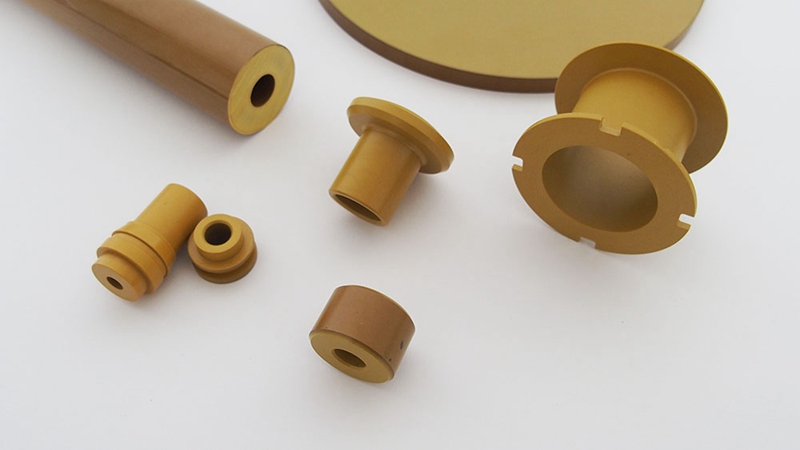

Torlon 4203 Pai Sheet Application

Semiconductor industry: test sockets, electronic connectors and insulators

Aerospace: Fasteners, insulators and other components

Oil and gas: natural gas compressor components, pump components and labyrinth seals

General industry: bearings and wear-resistant parts, as well as parts requiring high strength and high hardness

DURATRON (TORLON) 4203 PAI (yellow-ochre) (PAI)

DURATRON (TORLON) 4203 PAI offers the best toughness and impact strength of all DURATRON (TORLON) PAI grades. Because of its intrinsic high temperature resistance, high dimensional stability and good machinability, this extruded DURATRON (TORLON) PAI grade is very popular for precision parts in high-tech equipment. In addition, its good electrical insulating ability provides numerous possibilities in the field of electrical components.

Delivery Programme: rod 2.38 - 50.80 mm, plate 6.35 - 25.40 mm

DURATRON (TORLON) 4503 PAI (yellow-ochre) (PAI)

This compression moulded material is similar in composition to DURATRON (TORLON) 4203 PAI, and is selected when larger shapes are required.

Delivery Programme: rod 50.80 - 368.30 mm, tube 42.86 - 882.65 mm

DURATRON (TORLON) 4301 PAI (black) (PAI + graphite + PTFE)

The addition of PTFE and graphite provides higher wear resistance and lower coefficient of friction compared to the unfilled grade as well as little or no stick-slip in use. This extruded grade excels in severe wear applications such as non-lubricated bearings, seals, bearings cages and reciprocating compressor parts.

Delivery Programme: rod 2.38 - 50.80 mm, plate 6.35 - 25.40 mm

DURATRON (TORLON) 4501 PAI (black) (PAI + graphite + PTFE)

This compression moulded material is similar in composition to DURATRON (TORLON) 4301 PAI, and is selected when larger shapes are required.

Delivery Programme: rod 50.80 - 368.30 mm, plate 9.53 - 50.80 mm, tube 42.86 - 882.65 mm

DURATRON (TORLON) 5530 PAI (khaki grey) (PAI-GF30)

This compression moulded, 30 % glass fibre reinforced grade offers higher stiffness, mechanical strength and creep resistance than DURATRON (TORLON) 4203 PAI and DURATRON (TORLON) 4503 PAI. It is well suited for structural applications supporting static loads for long periods of time at high temperatures. The suitability of DURATRON (TORLON) 5530 PAI for sliding parts, however, is to be carefully examined since the glass fibres tend to abrade the mating surface.

Delivery Programme: rod 50.80 - 368.30 mm, plate 9.53 - 50.80 mm, tube 42.86 - 882.65 mm

Torlon Pai Sheet,Quadrant Pai Torlon 4203 Sheet,Torlon 4203 PAI,PAI sheet,PAI

Hony Engineering Plastics Limited , https://www.honyplastic.com