Combating Water Main Breaks with Carbon Fiber Technology

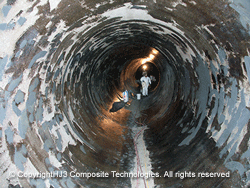

As summer approaches, many cities in northern regions are facing the aftermath of a harsh winter. Record low temperatures and heavy snowfall have left their mark, and now, as the weather warms up, we're seeing new challenges like snowmelt runoff and water main breaks. This period is commonly known as "water main break season," a recurring issue in many parts of the world. In Prince Albert, Saskatchewan, a persistent water main break has been flooding the streets for over a month, causing inconvenience and disruption. The Causes of Water Main Breaks One of the primary causes of water main breaks is the freeze-thaw cycle. As the ground thaws, it can lead to soil movement, putting pressure on underground pipes. Combined with extreme weather and aging infrastructure—some pipes are nearly 100 years old—this creates a perfect storm for failures. In Prince Albert alone, there have been 19 water main breaks this season, with more expected in the coming weeks. City officials are working on long-term solutions, acknowledging that the extreme cold last winter placed significant stress on the entire underground system. Corrosion: A Costly Problem Corrosion in pre-stressed concrete cylinder pipes (PCCP) is a major issue across North America. According to a 2002 study, corrosion costs U.S. water and wastewater systems over $50 billion annually. The country experiences more than 850 water main breaks every day, costing over $3 billion in annual repairs. Leaking pipes result in the loss of about 2.5 trillion gallons of drinking water each year—roughly 17% of all water pumped. Most of this loss is due to corrosion, which affects aging infrastructure. A 2012 study found that 43% of U.S. water mains are between 20 and 50 years old, while 22% are over 50 years old. With almost half of the one million miles of pipelines in the U.S. nearing the end of their service life, replacement costs are expected to exceed $1 trillion over the next 25 years. But with limited funding available, we need effective solutions to extend the life of our aging infrastructure. HJ3's CarbonSeal: A Game-Changer in Pipe Repair HJ3's CarbonSeal carbon fiber technology offers an innovative solution for repairing damaged pipes. At a coal-fired power plant, a 120-inch diameter pipe used to transport water to cooling towers suffered cracks in its internal concrete lining. Water seepage led to corrosion of the pre-stressed wires, compromising the pipe’s structural integrity. Instead of replacing the entire 750-foot section, the plant chose HJ3's CarbonSeal system. How the Repair Was Done The process began with abrasive blasting to clean the pipe surface, followed by polyurethane foam injection to seal leaks. After priming, saturated CarbonSeal fabric was carefully applied, and a protective top coat was added to ensure a waterproof finish. The entire repair was completed in just 11 days, restoring the pipe’s ability to handle internal stresses. Compared to traditional methods, this approach saved 50%, and 65% compared to full replacement. It also prevented six tons of concrete from going to landfills. After eight years, the system continues to perform reliably, meeting all expectations. The client praised HJ3 for the support provided throughout the project, including design calculations, engineering drawings, and on-site supervision. Looking for a Reliable Pipe Repair Solution? If you're dealing with underground pipe issues and want to explore HJ3's CarbonSeal reinforcement systems, reach out to HJ3 today. Their innovative technology offers a sustainable, cost-effective way to protect and extend the life of your infrastructure.

![PNM-1[1]](http://bsg-i.nbxc.com/blog/0cea1ad9232aeaed06638a149fc83342.jpeg)

The purpose of a wine bottle net bag is to provide a protective covering for a single bottle of wine during transportation. These bags are typically made of a stretchy mesh material that conforms to the shape of the bottle and provides a cushion against bumps and jostles.

Wine bottle Net Bags are commonly used by wine enthusiasts who want to transport a bottle of wine safely to a party or gathering. They are also used by wine retailers and distributors to protect bottles during shipping and handling.

The bags are designed to be reusable and can be easily washed and dried. They come in a variety of colors and styles, making them a popular choice for gift-giving as well.

Overall, wine bottle net bags are a simple and effective solution for protecting and transporting bottles of wine safely and securely.

Wine Bottle Net Bag,Bottle Protection Mesh Bag,Black Mesh Bag,Mesh Wine Bags

Suzhou Yitengjia Extruded Net Packaging Co., Ltd. , https://www.plasticnetbag.com