Combating Water Main Breaks with Carbon Fiber Technology

As summer approaches, many cities in northern regions are dealing with the consequences of a severe winter. Unusually low temperatures and heavy snowfall have left infrastructure under significant stress. Now, as the weather warms up, we're facing new challenges like snowmelt runoff and water main breaks—commonly referred to as "water main break season." In Prince Albert, Saskatchewan, a persistent leak has been flooding the streets for over a month, highlighting the urgent need for effective solutions.The Causes of Water Main Breaks

One of the primary causes of water main failures is the freeze-thaw cycle. As the ground thaws, it can cause uneven settling, putting pressure on underground pipes. Combined with aging infrastructure—some pipes are nearly 100 years old—this creates a perfect storm for frequent breaks. In Prince Albert alone, there have been 19 reported breaks this season, with more expected in the coming weeks. City officials admit that the extreme cold last winter placed immense strain on the entire underground system.Tackling Corrosion in Aging Pipelines

Corrosion in pre-stressed concrete cylinder pipes (PCCP) is a major issue across North America. A 2002 study found that corrosion costs U.S. water systems over $50 billion annually. On average, there are more than 850 water main breaks each day, costing over $3 billion in repairs. Leaks result in the loss of about 2.5 trillion gallons of drinking water yearly—roughly 17% of all water pumped in the U.S.—with 90% of this loss linked to aging, corroded pipes. A 2012 Utah State University study revealed that 43% of American water mains are between 20 and 50 years old, while 22% are over 50 years old.With almost half of the one million miles of pipelines in the U.S. nearing the end of their service life, replacement costs could exceed $1 trillion over the next 25 years. However, with limited funding available, finding a sustainable way to extend the lifespan of these critical systems is essential.

HJ3's CarbonSeal: A Game-Changer in Pipe Repair

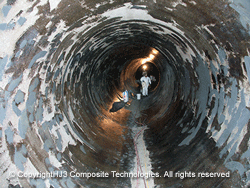

HJ3’s CarbonSeal carbon fiber technology offers an innovative solution for repairing damaged water mains. At a coal-fired power plant, a 120-inch diameter pipe used for cooling tower water had developed cracks, allowing water to seep into the concrete lining and corrode the internal wires. Faced with the high cost of replacement, the facility chose HJ3’s CarbonSeal system to repair 750 feet of pipe instead.How CarbonSeal Works

The process began with sandblasting the pipe surface, followed by polyurethane foam injection to seal leaks. The surface was then primed, and saturated CarbonSeal fabric was carefully applied. A protective top coat was added to ensure a waterproof finish. Remarkably, the entire 750-foot section was repaired in just 11 days, restoring the pipe’s structural integrity. This method saved 50% compared to other repair techniques and 65% compared to full replacement. It also prevented six tons of concrete from going to landfills. After eight years, the system continues to perform as expected, with the client expressing high satisfaction with HJ3’s support in design, engineering, and on-site supervision.Explore CarbonSeal for Your Pipeline Needs

If you're facing pipeline issues and want to learn more about HJ3’s CarbonSeal reinforcement systems, reach out to HJ3 today. Their advanced carbon fiber technology provides a reliable, cost-effective alternative to traditional repairs and replacements.

![PNM-1[1]](http://bsg-i.nbxc.com/blog/0cea1ad9232aeaed06638a149fc83342.jpeg)

A net bag for toys is a convenient and practical storage solution for children's toys. The main purpose of a net bag is to keep toys organized and easily accessible, while also reducing clutter in a child's room or play area.

Some benefits of using a net bag for toys include:

1. Easy to use: A net bag is simple to use and can be easily hung on a hook or nail, making it easy for children to access their toys.

2. Space-saving: A net bag takes up minimal space and can be hung out of the way, freeing up valuable floor space in a child's room or play area.

3. Breathable: The mesh design of a net bag allows for air circulation, which helps prevent musty odors and mold from developing on toys.

4. Durable: A net bag is typically made from strong, durable materials that can withstand the weight of multiple toys.

5. Versatile: A net bag can be used to store a variety of toys, including stuffed animals, balls, building blocks, and more.

Overall, a net bag for toys is a practical and effective storage solution that can help keep children's toys organized and easily accessible.

Net Bag For Toys,Mesh Bag For Sand Toys,Mesh Beach Bag For Sand Toys,Net Bag

Suzhou Yitengjia Extruded Net Packaging Co., Ltd. , https://www.plasticnetbag.com