Major Cement Company Improves Stockpile Measurement with Elios 3

Major Cement Company Enhances Stockpile Measurement with Elios 3

A leading cement plant in France has successfully implemented the Elios 3 drone equipped with LiDAR technology to improve clinker stockpile measurements. This innovative approach has significantly enhanced both safety and accuracy in inventory management.

Key Benefits at a Glance

|

Speed The entire process, from data collection to post-processing using GeoSLAM Connect, took just 30 minutes—10 minutes for flight and 20 minutes for analysis. This is far faster than traditional manual methods. |

Performance in Dusty Conditions Thanks to its 3D Live Map feature, the Elios 3 can navigate and collect data inside dusty silos where visibility is extremely limited. The real-time mapping ensures precise navigation even when the video feed is obscured. |

Safety Traditional methods required workers to stand on unstable platforms high above the silo, posing significant safety risks. The Elios 3 eliminates this danger by allowing remote, hands-off measurement of clinker stockpiles. |

Introduction

Clinker is a crucial raw material used in the production of cement. It is typically stored in large silos, and accurate inventory tracking is essential for efficient production planning. Traditionally, operators would manually measure the amount of clinker by standing on a platform and probing the pile with a pole, which was time-consuming and risky.

Customer Needs

The French cement plant faced several challenges with their manual clinker inventory process. Employees had to work in dangerous conditions, standing on a narrow, shaky platform 25 meters (82 feet) above the ground. Visibility was also poor due to dust, making the process not only inefficient but also unsafe.

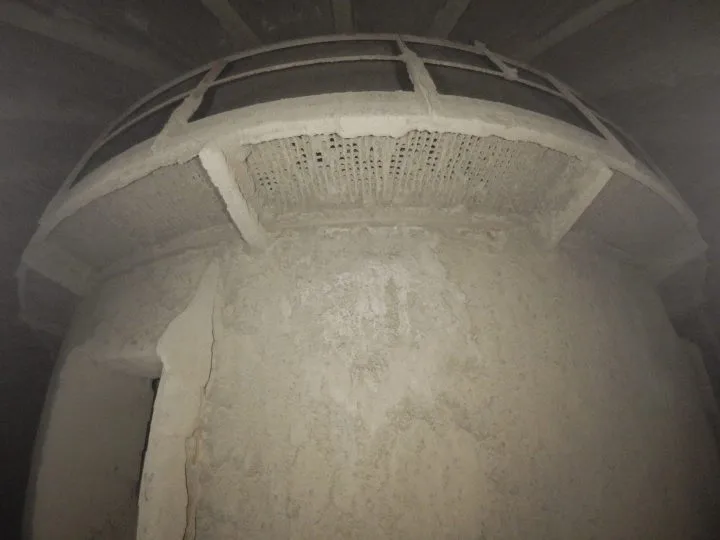

The clinker silo platform where personnel stand to collect inventory data

To address these issues, the plant sought a safer and more accurate solution for measuring clinker stockpiles.

Solution

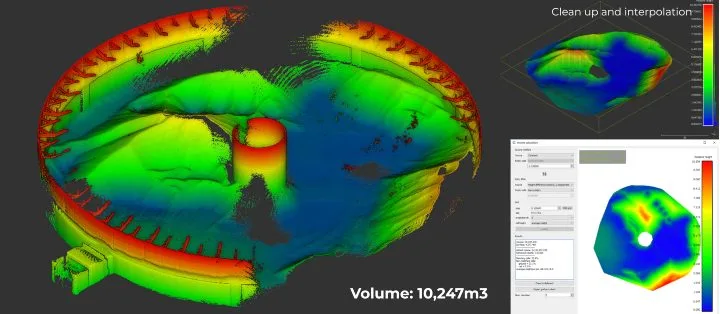

The plant decided to test the Elios 3 drone, which uses LiDAR technology to capture precise 3D data while flying. The goal was to use this data, along with GeoSLAM Connect software, to create an accurate volume measurement of the clinker stockpile.

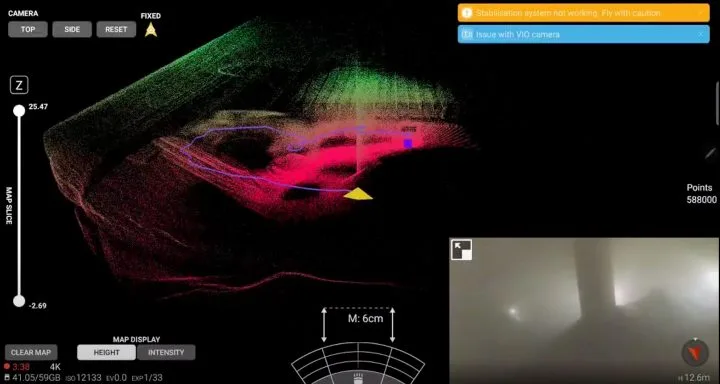

The Elios 3’s real-time 3D Live Map allows pilots to navigate even in low-visibility environments like dusty silos. This feature made it possible to fly safely and accurately without relying solely on the drone's camera feed.

3D Live Map of the clinker silo platform side-by-side with the live visual feed

Results

The implementation of the Elios 3 proved highly successful. The process was not only much faster but also significantly more accurate than the previous manual method. Operators were able to complete the task in just 30 minutes, including post-processing time.

The drone performed exceptionally well in the dusty environment, thanks to its LiDAR stabilization system. This allowed it to maintain stability and accuracy even when visibility was compromised.

Here are the main benefits the plant experienced:

- Speed: 10 minutes of flight time and 20 minutes of post-processing provided a highly accurate volume measurement.

- Accuracy: The Elios 3 delivered much more reliable data than manual methods.

- Dusty Environments: The 3D Live Map and LiDAR stabilization enabled safe and effective operation in high-dust areas.

- Safety: No employees had to climb onto the dangerous platform, reducing risk.

- Coverage: The 3D Live Map ensured full coverage of the clinker stockpile for comprehensive data collection.

The 3D Live Map made it possible to fly even in very dusty conditions inside the silo

Additional Visual Inspection of a Filter Shaft

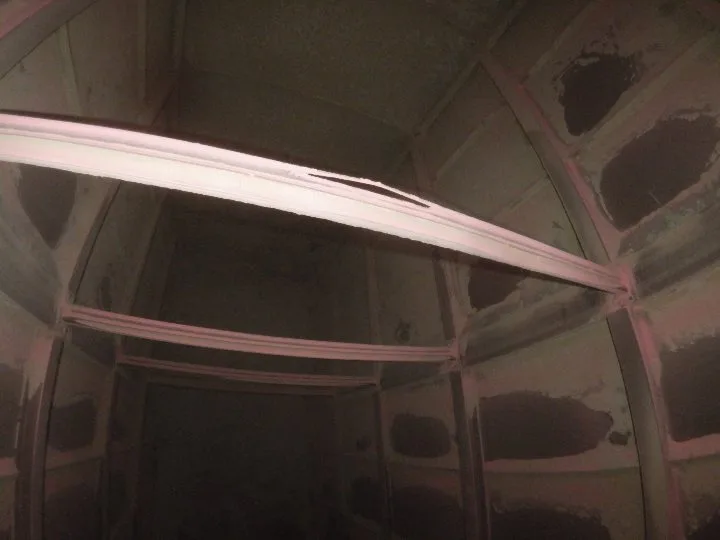

In addition to clinker inventory, the plant also used the Elios 3 to inspect a filter shaft. Inspectors suspected damage to the beams and wanted a close-up view. The drone revealed severe deterioration, enabling timely maintenance and preventing potential downtime.

Pictures of the deteriorated beams inside the filter shaft

Conclusion

The success of the Elios 3 in clinker inventory has led the plant to consider adopting it as a permanent solution. In addition to stockpile measurement, they are exploring its use for regular inspections of other critical assets within the plant.

With its ability to operate in dusty and low-visibility environments, the Elios 3 offers a versatile and reliable tool for industrial applications. Its combination of speed, accuracy, and safety makes it a valuable asset for any facility dealing with challenging operational conditions.

China leading manufacturers and suppliers of Wire Rope Clip,Stainless Steel Clip, and we are specialize in Din741 Steel Wire Rope Clip,Galvanized Steel Clip, etc.

We follow very strict incoming and outgoing QC procedures and have our own in-house inspection equipment, such as Spectrometers, Load testing machines, salt spray booth, along with being ISO9001 certified.

Please do not confuse Ruijin Co.ltd with other Chinese manufacturers, we strive to offer the very best quality product along with unparalleled customer service. We would welcome the opportunity to discuss your current and future requirements, and warmly invite you to visit our facility.

Wire Rope Clip,Stainless Steel Clip,Din741 Steel Wire Rope Clip,Galvanized Steel Clip

JIANGSU RUIJIN SLING CO.,LTD. , https://www.cnsteelcable.com