Have a power door lock issue on your Toyota Avalon? Get it fixed, here’s how.

Key Fob Doesn’t Unlock Doors, But Door Buttons Work

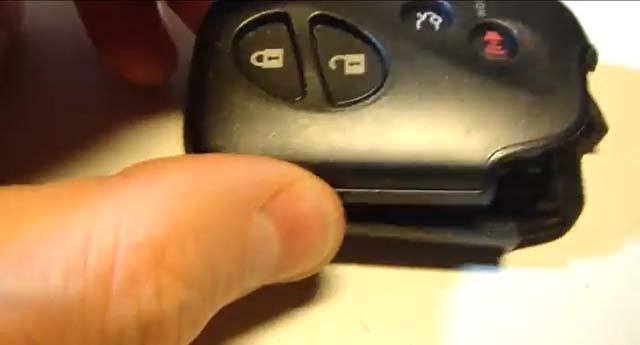

If your key fob isn't working but the buttons on the doors do, the issue is likely simple: a dead battery. Replacing the battery in your key fob is an easy fix that anyone can do at home. Here's how:- Hold the key fob between your fingers, avoiding the front buttons. Squeeze the sides gently until the back panel pops off.

- Inside, locate the small battery (usually a CR2032 or similar).

- Replace the battery with a new one of the same type and reassemble the key fob.

Your key fob may vary, but they are all essentially the same.

One Door Won’t Lock or Unlock

If only one door isn’t responding to the key fob or the power lock button, the issue is probably with the door’s actuator motor. These motors control the locking mechanism and can fail over time due to wear and tear. You might hear a buzzing sound before the motor completely fails. To fix this, you’ll need to replace the actuator. Here's how to access it:- Remove all visible screws from the door panel, including those near the door handle and speaker.

- Use a screwdriver to carefully remove the door handle and plastic trim around it.

- Gently pull the door panel away from the door. You may need to use a trim removal tool to pop off the retainers without damaging them.

All Doors or Multiple Doors Fail to Lock/Unlock

If several or all doors aren’t responding to the key fob or power lock buttons, the problem is more serious. This could be due to a faulty relay, a blown fuse, or wiring issues. These problems often require professional diagnosis and repair. It’s best to bring your Avalon to a qualified mechanic who can use diagnostic tools to identify the exact cause. Trying to fix this yourself could lead to further complications if you’re not experienced.Related Posts

Product Introduction:

Our MV pump is including Vertical Slurry Pump, Flotation Sump Pump, Screen Area Sump Pump. The MV/MVR heavy duty sump pump is designed for applications requiring greater reliability and durability. The bearing assembly allows the pump to operate in the "snore" condition without damage to the bearings. It is designed for handling abrasive slurries and corrosive fluids by using either elastomer or alloy lined wet ends components. The pump is suitable for mining, chemical treatment, waste water treatment, gravel and general process application.

Product Features:

-Fully elastomer lined or hard metal fitted

-Double suction semi-open Impeller

-No submerged bearing or packing

-Optional recessed impeller and suction agitator available

-MVR models feature full rubber covering for corrosion resistance

-Can be run in insufficient suction duties

Application Range:

Size: 40 to 250mm

Capacity: 17 to 1000 m3/h

Maximum head: 40m

Flotation Sump Pump,Coal Washing Pumps,Vertical Sump Pumps,Thickner Underflow Pumps

SHIJIAZHUANG MUYUAN INDUSTRY & TRADE CO., LTD. , https://www.cnmuyuan.com

Toyota RAV4 Door Lock Failure – Diagnose Guide

Toyota RAV4 Door Lock Failure – Diagnose Guide  Toyota Land Cruiser Door Lock Failure – Repair Guide

Toyota Land Cruiser Door Lock Failure – Repair Guide  Toyota Yaris Door Lock Failure Guide

Toyota Yaris Door Lock Failure Guide  Scion tC Power Door Lock Failure Guide

Scion tC Power Door Lock Failure Guide  Toyota Avalon Maintenance – Shock And Strut Replacement

Toyota Avalon Maintenance – Shock And Strut Replacement  Toyota Avalon Headlight And Taillight Replacement Guide

Toyota Avalon Headlight And Taillight Replacement Guide