904L is a type of austenitic stainless steel known for its excellent corrosion resistance across a wide range of environments. Its unique combination of alloying elements, including high levels of nickel, chromium, and molybdenum, provides it with remarkable durability and strength, even in extreme conditions. This makes 904L particularly suitable for use in harsh chemical environments where other materials might fail.

Table of contents

- Stainless Steel 904L Chemical Composition

- SS 904L Mechanical Properties

- Physical properties of INOX AISI 904L

- AISI 904L Welding Process

- SUS 904L Mean Coefficient of Thermal Expansion

- Corrosion Resistance of Alloy 904l

- Corrosion Rates of 904L Material

- Chemical Compatibility of Stainless Steel Alloy 904L

- UNS N08904 Material Temperature Range

- Type 904L Stainless Steel Thermal Properties

- AISI 904L Equivalent grades

- Specifications of SUS 904l Material

- SAE 904l Electrical Properties

- Din 1.4539 Applications

- Advantages & Disavntages of SS 904l Material

- Hot Forming of SUS 904l

- Cold Forming of SS 904L

- Machining of Stainless Steel Alloy 904L

Stainless Steel 904L Chemical Composition

SS 904L Mechanical Properties

| Grade | Yield Strength 0.2% Proof (MPa) min | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Brinell (HB) | Rockwell B (HR B) | ||||

| 904L | 220 | 490 | 36 | 150 | 70-90 typical |

Physical properties of INOX AISI 904L

| Density | kg/dm³ | 8 |

|---|---|---|

| Modulus of elasticity | GPa | 195 |

| Thermal Capacity | J/kg°C | 450 |

| Electrical resistivity | µΩm | 1 |

| Thermal conductivity | W/m°C | 15.8 |

Alloy 904l Has Excellent Formability and Weldability

This stainless steel is non-magnetic and highly formable, making it ideal for manufacturing complex shapes without compromising structural integrity. It also offers excellent weldability, allowing it to be joined using various techniques such as TIG, MIG, SMAW, PAW, and SAW. These features make 904L a versatile choice for a wide range of industrial applications.

AISI 904L Welding Process

- TIG

- MIG

- SMAW

- PAW

- SAW

SUS 904L Mean Coefficient of Thermal Expansion

| Yield Strength 0.2% Offset psi (MPa) | Ultimate Tensile Strength psi (MPa) | Hardness | Elongation in 2 in. % | ||

|---|---|---|---|---|---|

| 31,000 | 220 | 71,000 | 490 | 70 – 90 Rockwell B | 36 |

1.4539 Material is Known for Its Corrosion Properties

As a low-carbon, high-alloy austenitic stainless steel, 904L is widely used for its outstanding corrosion resistance, especially in acidic environments like sulfuric, phosphoric, and acetic acid. The addition of copper enhances its performance in chloride-rich solutions, providing excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Corrosion Resistance of Alloy 904l

- Good Resistance to Uniform Corrosion

- Temperatures up to 95°F (35°C)

- Concentration Range of 0 to 100%.

- A Nickel content of 25%, 904L is a good Alternative

- Susceptible to Chloride Stress Corrosion Cracking

- 904L Have Good Resistance to SCC

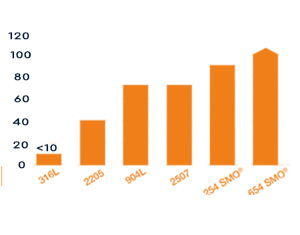

Minimum Stress For Failure % of Rp0.2 at 200°C

Typical threshold stresses determined using the drop evaporation test.

Temperature, °C

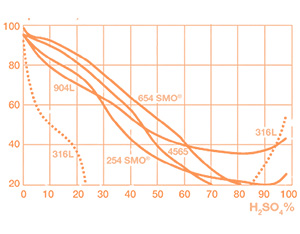

Isocorrosion curves 0.1 mm/year, in pure sulphuric acid.

Corrosion Rates of 904L Material

| Uniform corrosion | Corrosion, (mm/year) |

|---|---|

| pickling acid at 25°C | 0.47 |

| wet process Phosphoric acid at 60°C | 1.2 |

| Distillation of Tall oil at 253°C | 0.06 |

SUS 904l Has High Concentrations of Chromium, Nickel and Molybdenum

These elements contribute to its exceptional corrosion resistance, especially against chloride stress corrosion cracking and general corrosion. It is well-suited for use in environments where other steels would corrode rapidly, making it a preferred choice in chemical processing and marine applications.

Chemical Compatibility of Stainless Steel Alloy 904L

| Chemical | Compatibility |

|---|---|

| Sulfuric Acid (Hâ‚‚SOâ‚„) | Good resistance ; avoid concentrated acid. |

| Hydrochloric Acid (HCl) | Better resistance compared to many other stainless steels, especially at lower temperatures. |

| Nitric Acid (HNO₃) | Good resistance, particularly up to 65% concentration at room temperature. |

| Phosphoric Acid (H₃PO₄) | Good performance in moderate concentrations and temperatures. |

| Sodium Hydroxide (NaOH) | Resistant, especially in lower concentrations |

| Sodium Chloride (NaCl) | Resistant but prone to stress corrosion cracking in high chloride environments. |

| Acetone | Generally compatible. |

| Ethanol | Generally compatible. |

| Formic Acid | Shows good resistance. |

| Oxidizing Agents | Resistant to many oxidizing agents. |

| Hydrogen Sulfide (Hâ‚‚S) | Susceptible to stress corrosion cracking, especially under high temperature. |

SS 904l is Heat Resistant Alloy Designed for High Temperature Structural Applications

Its ability to withstand both heat and corrosion makes it an ideal choice for high-temperature environments. It is commonly used in industries such as petrochemicals, power generation, and chemical processing, where materials must endure aggressive conditions without losing their mechanical integrity.

UNS N08904 Material Temperature Range

| Temperature Range | Performance |

|---|---|

| Cryogenic Temperatures (< -200°C / -328°F) | Generally suitable |

| Ambient to Moderate Temperatures (up to ~400°C / 750°F) | Excellent performance |

| High Temperatures (~400°C to 800°C / 750°F to 1470°F) | Capable of withstanding moderate temperatures |

| Exceeding 800°C / 1470°F | The material is generally not recommended for such high temperatures. |

Type 904L Stainless Steel Thermal Properties

| Thermal Properties | Metric | English |

|---|---|---|

| CTE, linear | 15.3 µm/m-°C Temperature 20.0 – 100 °C |

8.50 µin/in-°F Temperature 68.0 – 212 °F |

| 16.5 µm/m-°C Temperature 20.0 – 400 °C |

9.17 µin/in-°F Temperature 68.0 – 752 °F |

|

| 18.2 µm/m-°C Temperature 20.0 – 800 °C |

10.1 µin/in-°F Temperature 68.0 – 1470 °F |

|

| Specific Heat Capacity | 0.460 J/g-°C | 0.110 BTU/lb-°F |

| Thermal Conductivity | 11.5 W/m-K Temperature 20.0 °C |

79.8 BTU-in/hr-ft²-°F Temperature 68.0 °F |

| 12.9 W/m-K Temperature 100 °C |

89.5 BTU-in/hr-ft²-°F Temperature 212 °F |

Refer 904l Material Equivalent, Composition and Specification

The equivalent grade of 904L allows users from different countries to identify and procure the same material easily. This ensures consistency in quality and performance, which is essential for international trade and standardization. Understanding the composition and specifications helps in selecting the right material for specific applications, ensuring optimal performance and longevity.

The chemical composition of 904L is carefully balanced to provide a combination of strength, ductility, and corrosion resistance. Elements like nickel and molybdenum play a key role in enhancing its performance in harsh environments, while the low carbon content reduces the risk of intergranular corrosion during welding.

Specifications define the standards that 904L must meet in terms of mechanical properties, chemical composition, and physical characteristics. These standards ensure that the material performs reliably in its intended application, whether it's in chemical processing, marine environments, or high-temperature systems.

AISI 904L Equivalent grades

| Grade | UNS No | Old British | Swedish SS | Euronorm | ||

|---|---|---|---|---|---|---|

| En | BS | No | Name | |||

| 904L | N08904 | – | 904S13 | 2562 | 1.4539 | X1NiCrMoCuN25-20-5 |

Specifications of SUS 904l Material

- Trade Names :SS 904L, AISI 904L, INOX 904L, SUS 904L, Stainless Steel 904L, 904L Steel, ASTM 904L

- Benefits :Non-magnetic, Excellent corrosion properties, Good resistance to sulphuric, Excellent formability and weldability

- Tempraturer Range :850 °C – 1150 °C

- Features :Lower carbon content leads to resistance to sensitization when welded, Increased resistance to chemical attack from acids

SAE 904l Electrical Properties

| Electrical Properties | Metric | English |

|---|---|---|

| Electrical Resistivity | 0.0000952 ohm-cm | 0.0000952 ohm-cm |

| Magnetic Permeability | <= 1.02 | <= 1.02 |

Din 1.4539 Applications

- Organic Acid Treatment System

- Sea Water Heat Exchanger

- Paper Industry Equipment

- Heat Exchangers

- Condenser Tubes

- Gas Scrubbing Plants

- Pulp and Paper Processing Industries

Advantages & Disavntages of SS 904l Material

Advantages

- Excellent Corrosion Resistance

- Good Strength and Toughness

- Good Formability & Durability

- It is Non-magnetic in the Annealed Condition

Disadvantages

- Expensive Material

- Not Ideal for Very High Temperatures

- Extremely High-temperature Applications

- Potential for Work Hardening

Hot Forming of SUS 904l

- Working temperatures:1562 – 2102°F (850 –1150°C)

- Forming Techniques:Forging, rolling, or extrusion

- Solution Annealed:1940 – 2084°F (1060 –1140°C).

- Partial Heating or Cooling :below 2012°F (1100°C)

Cold Forming of SS 904L

- Work Hardening: work-hardens significantly, cold working might require intermediate annealing.

- Nitrogen Implies more powerful processing equipment

- Ductile and Forms Easily

Machining of Stainless Steel Alloy 904L

- Makes it less Machinable

- More Challenging due to work hardening

- Using proper tooling and cutting fluids.

A backhoe loader is a single unit consisting of three pieces of construction equipment.Commonly known as "two busy".During construction, the operator only needs to turn the seat to change the working end.The main job of the backhoe loader is to dig trenches to arrange pipes and underground cables, lay foundations for buildings and establish drainage systems.

Backhoe loaders are compact compared to larger, single-function equipment such as track-type excavators.And they can also move around on various construction sites, and even run on the road.While some compact loader and Excavator equipment may be smaller than a backhoe loader, contractors who perform both excavation and loading operations can save a lot of time and money by using a backhoe loader.

Backhoe Loader,backhoe for sale,backhoe loader for sale,mini backhoe loader

Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com